REULAND - TTHE MOST FLEXIBLE ELECTRIC MOTOR MANUFACTURER IN THE WORLD - HEAVY DUTY AND SPECIALTY ELECTRIC MOTORS

With Experience comes versatility. Reuland has been engineering electric motors since the 1930s. Whether you need a robust efficient heavy duty motor, or a high precision specialty electric motor, Reuland delivers.

Reuland, Industry plant, utilizes lean manufacturing techniques within its multiple machine shop operations. Work cells assist in processing various aluminum, steel, and brass motor components. Machinery and equipment can be quickly converted or re-tooled to begin production on the next series of motor orders or motor components. It's this production conversion and lean manufacturing techniques that assist Reuland in relatively short motor production lead-times.

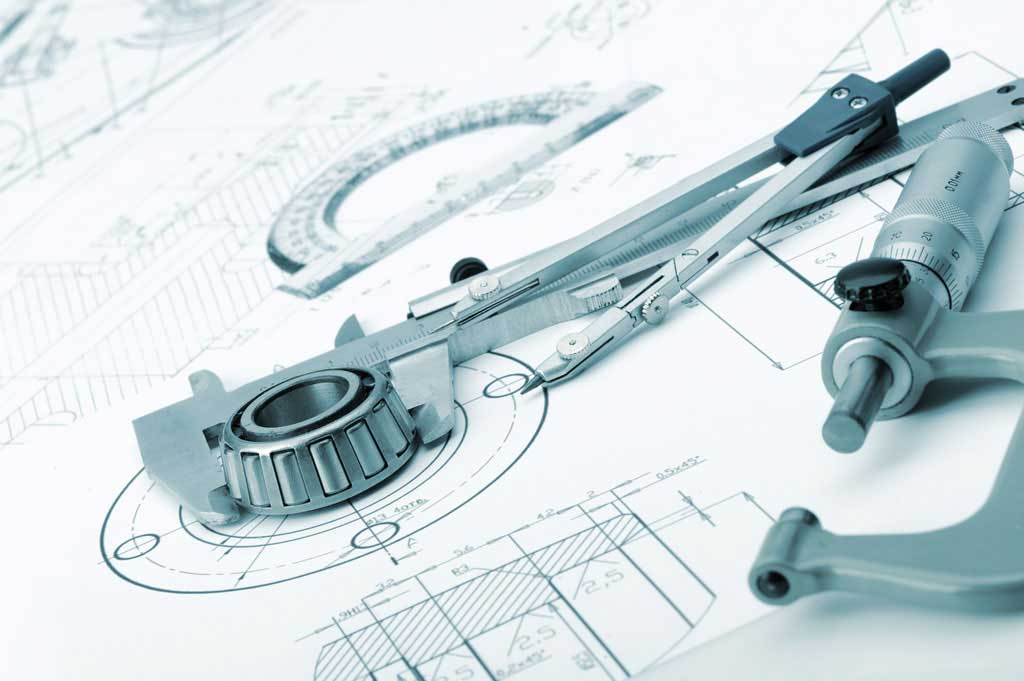

Reuland, Industry Plant, utilizes CNC machining centers to process various motor part components. Programmed CNC machining centers allows Reuland to efficiently and with precision, meet exacting customer specifications and production design processing tolerances. Reuland's quality is simply "Quality is Our Top Priority."

Reuland, Industry plant, Foundry Pattern Shop. Because Reuland utilizes its own fully functioning aluminum foundry, production demands, or more specifically, pattern tooling demands vary from week-to-week, customer-to-customer, project-to-project, etc. Pattern tooling drives production schedules and can impact product and production design, schedules and efficiencies. Reuland houses its own Pattern Shop or foundry tooling department. The department utilizes time tested and proven techniques to design and produce foundry production tooling to meet extremely demanding operational foundry process conditions. Reuland prides itself on the design staff with well over fifty years of collective tooling production knowledge. Again, it's with this flexibility in design and tooling production capabilities that makes Reuland a premier motor manufacturer.

Reuland, Industry plant, final assembly area. Reuland utilizes classic MRP driven inventory and production techniques. From the conception of the order through motor or product casting production, motor component production and stock releases to final assembly, product parts or components release systematically and efficiently allowing Reuland to control production schedules and control production schedule lead-times as well as handle a vast variety of various types and sizes of custom and standard motors and motor products. It's this level of detail and commitment to production and our customers that helped Reuland become a leader in both basic and specialty motor and motor product applications.

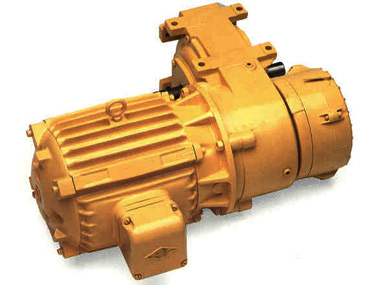

Reuland variable speed, inverter duty motors are available in both open loop and closed loop designs. Series 100 and Phasor2000 styles are designed and manufactured for the most demanding applications. Closed loop designs will handle up to 1000:1 constant torque requirements and full torque at zero speed. Reuland's unique slot designs minimize the heating and noise effects induced by drive switching frequencies (harmonics) and eliminate typical cogging at low frequency operation. Variable speed designs are also available with wide constant power ranges often required in machine tool spindle applications. Variable speed motors are available from fractional horsepower through several hundred horsepower in open, enclosed and blower cooled enclosures, continuous or intermittent duty. Use of variable speed motors spans a multitude of applications. Machine tools, material handling, pumps, fans and elevators, to name a few.

Reuland builds motors from the ground up ... we develop the design and produce the prototype.

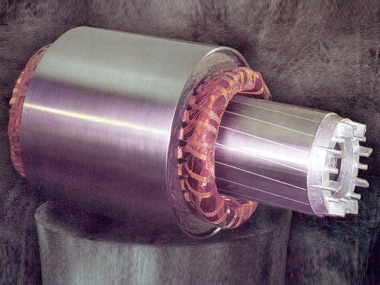

We're very careful to produce the highest quality product and meet your delivery schedule. Every stator is hand wound for the greatest flexibility required by application demands.

Reuland permanent magnet design parameters are flexible to meet any performance requirements you may have in mind.

Look to Reuland for permanent magnet motors with unsurpassed power factor and efficiency ... featuring high density power where required for a variety of applications; synthetic fiber and glass production machinery, machine tool transfer line, wire drawing, packaging and folding machinery and conveyor line drives and medical equipment, etc.

Here's When To Use Synchronous Permanent Magnet Motors: When you need synchronization from process to process during production. When you need precise control over the speed of the process during production. When you need total tension control during manufacturing processes.

Reuland Permanent Magnet Motor Features and Benefits: Precise speed control High efficiency and high power factor ... you get as much as 20% higher efficiency over conventional synchronous type motors and as much as 30% higher power factor that uses less current than conventional synchronous motors.

Reduced operating expenses ... there is no need to buy tachometers and regulators that are required by D.C. drive systems when you use Reuland permanent magnet synchronous motors. Stable magnets ... Reuland's maximum energy density permanent magnets allow the motor to be smaller and lighter than conventional synchronous motors ... Reuland magnets feature high coercive force to prevent the motor from demagnetizing at over voltage condition.

Motors that can be customized ... special flanges and shafts are available to meet your specific motor requirement. Motors that are self-braking ... there is not need for D.C. power to brake Reuland permanent magnet motors, since the motor braking can be accomplished by simply shorting the motor leads.

Construction Features: Condor Series Permanent magnet motor construction options include: cast iron aluminum stainless steel water cooled partial motors available (rotor/stator sets) Reuland's Condor Series permanent magnet synchronous motors are available in NEMA frames 56 through 256 (IEC optional) in 2 pole, 4 pole and 6 pole configurations. Constant or adjustable frequency up to 300 Hz available with up to 600 volt designs. Other construction features include: Speeds up to 18,000 rpm Constant torque applications Class F or H insulation with Class B rise Here's the application data required to quote a Reuland Permanent Magnet motor: Load Inertia Acceleration Time Pull-in and Pull-out torque Frequency and Speed Range Voltage at Maximum Speed Power Supply Type Duty Cycle Ambient Condition Enclosure.

Our popular MagnaStop brake is a solenoid activated, spring set type brake. The MagnaStop brake is available in standard and dust-tight/waterproof enclosures in standard AC voltages. Torque ratings available range from (1.5-20) lb. Ft. The brake can be ordered as a traditional C-face mount or as a "double C-face" design. The MagnaStop can also be ordered as foot mounted design.

Reuland also offers a wide range of direct acting magnetic disc brakes. These brakes are also available as standard, dust-tight/waterproof, or marine duty enclosures. Torque ratings available vary from 1.5 to 1000 lb. Ft. Reuland brakes are defined as "fail safe". When power is applied to the brake, the brake releases the motor shaft. The load is then free to turn. When power is removed or lost, the brake grabs the motor shaft and stops the load. A brake release knob or flipper is provided to manually release the brake. We offer both adjustable and non-adjustable designs. Reuland brakes are available in both single and three phase designs. Some brakes are available in DC power. Finally, Reuland offers it's "X" series brakes. These brakes are designed to mount to non-Reuland built motors.

Partial or "shell" motors are AC induction, squirrel cage stator and rotor sets. Partial motors range from small fractional horsepower units to several hundred horsepower. The wound stator core is available either as a machined core or with a shell housing to match most any existing diameter requirement. The rotor is available with standard or special machined bores. The user may design partial motors into their equipment and provide whatever means of cooling preferred. High-speed designs are available up to 1500 hertz.

Common applications are motorized spindles, pumps, small hoist motors, drilling and boring machines, routers, arbors, grinders or most any application where the motor must be built-in to another component.

AC induction, squirrel cage elevator motors may be two speed, single speed or variable speed (VVVF). Traditionally a DC machine, AC variable frequency is today's state of the art prime mover for most elevators. Low slip, closed loop vector duty motors are available from 5 to 200 horsepower 4, 6, 8 or 10 pole. Reuland's unique electrical and mechanical designs are ideally suited for the demanding low noise levels and positioning requirements required for this application.

New construction and modernization (retrofitting existing old DC installations) for traction machines is where Reuland's expertise lies. Many older DC machines utilized special flange mount, single bearing motor designs and Reuland has developed a/c "drop-in" replacements for all styles and manufacturer's machines such as Westinghouse, Otis, Titan, Northern, Armor, and Dover. Our bolt-up designs eliminate the need for costly adapters and modifications to standard flange mount motors.

Reuland's crane and hoist motors have been the corner stone of our company for over 50 years.

Widely recognized by both the Crane Manufactures Association of America (CMAA) and the Hoist Manufactures Institute (HMI), a wide variety of designs and enclosures from fractional to 250 horsepower are available.

Motors can be ordered in 1800, 1200, 900, 720, and 600 rpm. Hoist designs from severe service to standby exist. Likewise, bridge and trolley motors from continuous service to infrequent duty are available. These motors come be both AC induction and Wound Rotor designs.

Typical crane & hoist duty motors are 15, 30, and 60-minute designs in open drip proof or non-ventilated enclosures. However, we offer a wide selection of alternate or custom duty ratings. For example, wound rotor motors are available in 120-minute duty as fan cooled or non-ventilated designs while scrap-handling cranes can be rated continuous duty as blower cooled units.

Reuland has pioneered the development of high speed, AC, squirrel cage motors for over 15 years and is recognized as a world leader in this market. Over 1000 designs exist for high speed, low power; high speed, high power and high speed, low inertia, high response machines. Ratings such as 500 HP, 10,000 RPM and 75 HP, 40,000 RPM are common. High-speed Partial motors are available up to 100,000 RPM. Each motor can be tailored to the User's specific load/speed ranges, high torque at low speed, and wide constant power ranges.

High speed motors are commonly used with machine tools, motorized spindles, grinders, routers, pumps, arbors, test stands, dynamometers, centrifuge drives and replacing costly speed increasers.

Why should you specify Reuland Flexible Couplings? Reuland uses stronger materials.

Because flexible couplings are subjected to constant torque and stress, they eventually wear out. Obviously, the longer the coupling lasts, the more value you get for your money.

The key to flexible coupling longevity is the elastomeric element that is sandwiched between the coupling halves. Most flexible coupling manufacturers use compression-molded, rubber-like materials for their standard grommets. Reuland, however, uses a high-tech injection molded material called Lomod for our standard grommets. Torque tests and shock loads prove Lomod is stronger and more durable than most of our competitors' standard elastomeric elements.

Reuland flexible couplings cost less. Lomod is priced like a standard grommet while providing the performance and specifications of a premium selection. This allows us to offer you a superior product that saves you money when you purchase it ... and that continues to save you money with lowered maintenance and replacement costs.

Reuland flexible couplings are made from lightweight aluminum. Our flexible couplings are lighter than steel and cast iron couplings, which helps prolong bearing and seal life on pumps, gearboxes and motors. Our lightweight aluminum couplings also cost less to ship to your location.

Reuland flexible couplings are precision machined. By maintaining tight tolerances, we help eliminate vibration and noise. Alignment is easily made with a straight edge and a feeler gage. Reuland flexible couplings offer double set screws standard. Most manufacturers charge you extra for a double set screw option. Since our couplings are designed to be the finest on the market we make double set screws standard on all coupling sizes. The extra set screw offers greater hoop stress generation, creating a more secure fit from coupling to shaft.

Rigorous Quality Control. We design and manufacture all flexible couplings ourselves. And we subject each one to exacting quality control inspections. This total control allows us to offer you higher quality at a lower price.

Specials, Metrics and Splines. Reuland offers one of the industry's largest selections of standard flexible couplings. In addition, splines, metric bores and keys, and other special options may be available from stock. If not, we can modify any flexible coupling to your exact specifications. Please consult the factory for your special needs.

The One Source for all Your Flexible Couplings and Pump/Motor Adapter Needs. When you connect a pump to a motor, you want a perfect alignment for optimal performance. And that's what you get when you specify flexible couplings and pump/motor adapters from Reuland. These two components work together to achieve near-perfect concentricity. Together they reduce vibration, heat noise and wear and tear. In short they're your best guarantee for increased performance and life expectancy.

Fast Delivery. Our flexible couplings are stocked in Reuland's Midwest and West Coast facilities for fast response and reduced transportation costs. Most orders are shipped within 24 hours of receiving your order.

The Reuland Guarantee. All Reuland products are covered by our quality and service guarantee. You must be satisfied with the quality of a Reuland flexible coupling or we'll replace it. Complete details of our Quality and Service Guarantee are listed on our flexible coupling policy sheet.

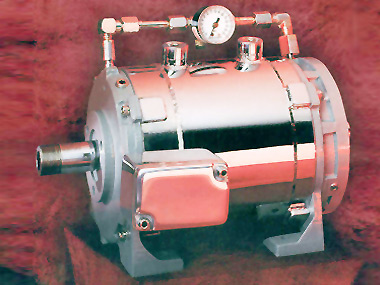

Marine and Coast Guard Duty Motors

Reuland marine duty motors utilize quality components in configurations designed for the riggers of the marine environment. Reuland marine duty motors utilize sealed construction, corrosion protection and high-grade insulation systems. Reuland motors have been performing in these environments for over 50 years and are made in compliance to specifications IEEE-45, American Bureau of Shipping (A.B.S.), and United States Coast Guard (USCG), and IEC 60092.Navy Service A and C Motors

Reuland Navy Service motors meet all pertinent Mil specs for fractional and integral hp motors for these applications including MIL-M-17060 and high impact shock per specification MIL-S-901. Our designs comply with all specifications related to shock & vibration, efficiency, sealed insulation systems, weight, materials, procurement, testing, air borne noise limits and structure borne noise limits.Motors for this class of duty conform to ALL the requirements of Mil-M-17060. Housings and end brackets are built with steel or ductile iron. Material traceably is provided through the Reuland quality assurance program in compliance with Mil Standards. These motors use VPI sealed insulation systems, corrosion proof hardware, and corrosion resistant coatings that meet Navy Service A requirements. All Motors are tested for performance and any other specified requirements.

Reuland Electric has been providing sophisticated custom motors for demanding shipboard applications for over 50 years. Our experience in both above and below deck applications makes us the manufacture of choice for many shipbuilders. Contact your local Reuland Electric Representative for more details.